When it comes to small equipment, longevity and consistent performance are paramount. Whether you’re a DIY enthusiast or a professional tradesperson, you rely on your tools to get the job done right, day in and day out. Neglecting routine maintenance can lead to unexpected breakdowns, costly repairs, and significant downtime. The good news is that with a little proactive care, you can significantly extend the life of your equipment and ensure it operates at peak efficiency. This guide will walk you through four essential maintenance practices that will help you protect your investment and keep your tools running smoothly for years to come.

1. Implement a Consistent Cleaning Routine

It may sound simple, but keeping your equipment clean is one of the most effective ways to prevent premature wear and tear. Dust, debris, grease, and moisture can accumulate over time, leading to corrosion, overheating, and mechanical failure. For example, clogged air vents can cause a motor to overheat, while dirt in moving parts can create friction and strain, eventually causing components to fail.

After each use, take a few minutes to wipe down your equipment with a clean, dry cloth. Use a brush or compressed air to clear out vents, crevices, and other hard-to-reach areas. For tools that come into contact with grease or oil, use a mild solvent to remove residue. Establishing this habit not only keeps your equipment looking good but also allows you to spot potential issues like leaks or loose parts before they become major problems. A study by a leading equipment manufacturer found that regular cleaning can prevent up to 30% of common equipment failures.

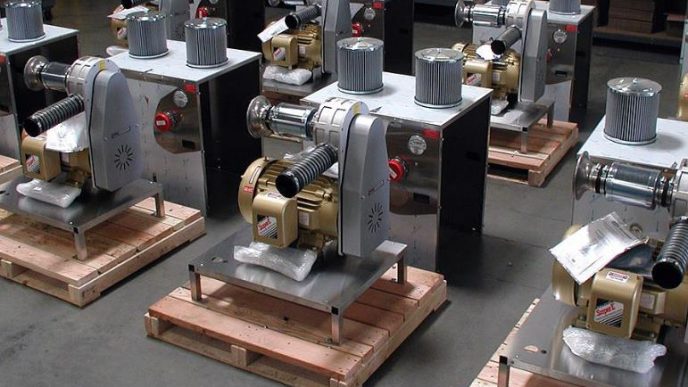

2. Prioritize Proper Lubrication

Just as your car’s engine needs oil to run smoothly, many types of small equipment require proper lubrication to function correctly. Moving parts create friction, which generates heat and causes wear. Lubrication reduces this friction, allowing components to move freely and efficiently, which in turn extends their operational life. Without it, parts can grind against each other, leading to irreversible damage.

Always consult your equipment’s manual to determine the correct type of lubricant and the recommended application schedule. Some tools have sealed bearings that don’t require lubrication, while others have specific oiling points. For instance, many pneumatic tools need a few drops of oil in the air inlet before each use. Similarly, some models of an air compressor oil less design are built to minimize maintenance, but others still require specific checks to ensure long-term performance. Over-lubricating can be just as harmful as under-lubricating, as excess oil can attract dirt and clog components, so follow the manufacturer’s guidelines precisely.

3. Conduct Regular Inspections and Minor Adjustments

Before you power up your equipment, get into the habit of performing a quick visual inspection. This simple practice can help you catch small issues before they escalate into serious failures. Check for loose bolts, frayed cords, cracked housings, and worn-out accessories like blades or bits. A vibrating tool might just need a screw tightened, but if ignored, that vibration could lead to more significant structural damage.

Pay close attention to power cords and hoses, as they are often the first components to show signs of wear. A damaged cord is not only a performance issue but also a serious safety hazard. If you notice any signs of damage, replace the part immediately. Additionally, ensure all safety features, such as guards and emergency stops, are in place and functioning correctly. Keeping a small toolkit handy for minor adjustments can save you from a major headache down the road. This proactive approach ensures both safety and reliability.

4. Ensure Correct Storage and Handling

How you store your equipment when it’s not in use is just as important as how you care for it during operation. Exposure to extreme temperatures, humidity, and direct sunlight can degrade plastic components, promote rust on metal parts, and damage sensitive electronics. Storing your tools in a clean, dry, and climate-controlled environment is ideal. A designated cabinet, toolbox, or wall-mounted storage system can protect your equipment from accidental damage and keep your workspace organized.

Proper handling also plays a crucial role. Avoid dropping your tools or using them for tasks they weren’t designed for. Using a screwdriver as a pry bar, for instance, can damage the tip and compromise its effectiveness. When transporting your equipment, secure it properly to prevent it from moving around and sustaining damage. Following these storage and handling best practices will protect your tools from environmental and accidental harm, ensuring they are ready to perform whenever you need them.