Use in chilling and cleaning, among other industrial settings. A constant and continuous air curtain is produced by its high-velocity air blower. controlled air flow through a long opening. The Industrial Air Knife Blower noise level, energy efficiency, and adaptability in industrial operations make it a reliable and cost-effective choice for air-based applications. is designed to remove unwanted substances including water, dust, dirt, and debris from surfaces. Air knife systems are widely used in manufacturing, food processing, packaging, the automotive industry, and other areas.

efficient cleaning and drying. By providing robust and dependable airflow, air knife systems guarantee efficient surface cleaning and drying. They may remove contaminants and moisture particles from items, containers, conveyor belts, and more. controlled air speed. Many air knife systems have adjustable air velocity settings that allow users to customize the airflow to meet their needs. For a variety of applications, this flexibility and agility offer the optimum performance.

Compressed air powers air knives.

There have always been a variety of blow-off devices. Compressed air blow-off nozzles and air knives come in a variety of forms, from homemade spherical pipes with holes to specially produced high pressure air knives. In order to maximize the effectiveness of using compressed air, several manufacturers of compressed air knives use the Coandă effect to improve the design of their blades in comparison to other types of knives and nozzles. The air knives, which draw inspiration from Coanda, draw ambient air into the

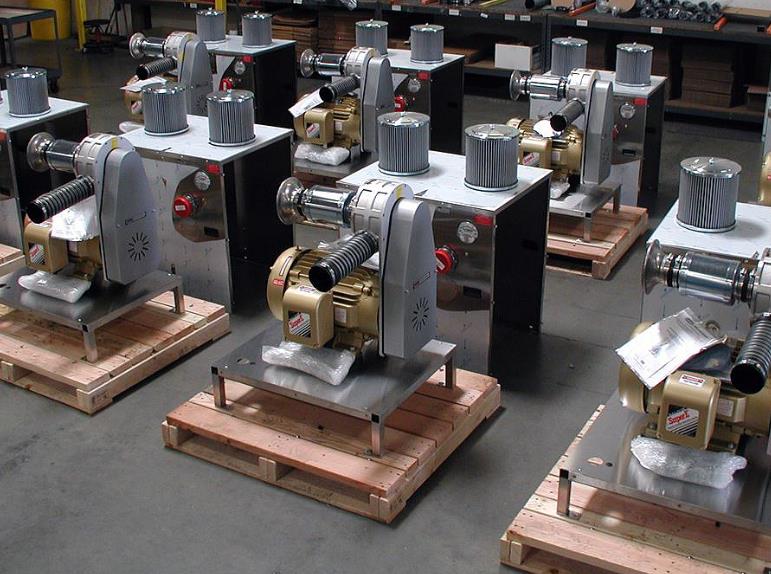

Air knives that use blowers

The teardrop-shaped air knife, which is the industry standard for blower-driven air knives, has a bulbous plenum that tapers down to a precise air discharge slit. With a coefficient of discharge of 0.95 (95% efficient), the teardrop-shaped air knife provides a much higher impact air velocity to the surface at which the air is aimed while requiring the least amount of blower motor power. A spherical pipe with holes drilled in it, on the other hand, usually has an average coefficient of discharge of 0.6 (60% efficient). These teardrop designs are available in extruded aluminum shapes and manufactured carbon and stainless steels.

In most manufacturing applications, the air knives stay still while the product moves through the air velocity air stream. In other circumstances, the object stays still while the air knives travel

Air knife systems have several uses. These are some of the most popular applications:

- Blow-off and drying operations in industrial processes

- Cleaning and removing waste from objects, surfaces, and containers

- In packaging procedures, parts are separated and ejected.

- Static management and the removal of electrostatic charges

- Web cleaning for the printing and conversion industries

across its surface by rotating or reciprocating. Although there are relatively few circumstances in which air knives may really cut a product (break mechanical links between two points), they are often the most effective technique to remove or regulate unwanted or foreign particles on any surface. In the galvanizing industry, air knives are used to precisely control the amount of coating by scraping the zinc coating from the steel surface while it is still liquid.

With a precision of plus or minus 5 grams/meter squared, a computer can independently control the top and bottom coated surfaces in most hot dip applications through a feedback loop. Most air knife systems for this purpose employ hot nitrogen gas as the cleaning agent rather than ambient air. Using nitrogen reduces the oxidation of the base metal.