Ever wonder why your online order is late, or why your favorite product just disappeared from store shelves? It’s not magic, and it’s not laziness. Modern industrial operations are working harder than ever—and yet somehow falling behind. The systems that fuel our daily conveniences are battling old infrastructure, labor shortages, climate surprises, and tech that moves faster than anyone can keep up with. So, what exactly is breaking down behind the scenes?

Part of the problem is how much we’ve come to expect from industry without noticing what it takes to keep things running. Behind every fast delivery is a web of factories, workers, machines, and logistics networks that must work perfectly together. But perfection is rare, especially when the world keeps throwing curveballs.

Supply Chains: Still Not Okay

If you thought supply chain issues vanished with the end of pandemic lockdowns, think again. Ports are still congested. Freight is expensive. And finding a reliable shipping route can feel like a roulette wheel. A single delay in one country can ripple through dozens of others. For businesses trying to meet deadlines or keep costs predictable, this constant uncertainty is exhausting.

Adding to the chaos, companies are rethinking how they store and move products. Many have started to buy shipping containers in bulk so they aren’t reliant on unpredictable leases. Having containers on hand gives them flexibility—an essential advantage when global systems are anything but stable. Still, storage and transportation costs remain high, and shifting routes to avoid conflict zones or climate disasters isn’t cheap or simple.

Labor: The People Problem

Factories need people, but those people are harder to find than ever. The skilled labor shortage isn’t just about retiring baby boomers. Younger workers are avoiding manufacturing jobs in favor of tech or remote roles. Even entry-level positions are tough to fill when better-paying, less physically demanding jobs are available elsewhere.

Training programs haven’t caught up to modern industrial needs, either. As machines get smarter, workers need new skills to run, monitor, and fix them. Without major investments in workforce development, the talent gap will only grow. And when companies do find great workers, keeping them happy and safe requires more than just a paycheck.

Data Overload: When Information Becomes a Hurdle

Modern industrial systems collect more data than ever before. From sensor readings on machinery to real-time inventory tracking, every operation is now monitored, measured, and logged. In theory, this should make things run smoother. But in practice, many companies are drowning in information they don’t know how to use.

Without the right tools or trained analysts, raw data becomes just another burden. Decisions get delayed because no one can interpret the numbers fast enough. Worse, bad data can lead to bad calls—like over-ordering materials or misjudging demand. Smart operations aren’t just about having data; they’re about using it wisely.

Technology: Too Fast or Not Fast Enough?

Automation is everywhere, but it’s not always smooth. Some companies are racing to adopt robotics and AI, while others are stuck using outdated systems because upgrades are too expensive. This mismatch creates wide gaps in productivity, efficiency, and quality control.

For those that do automate, there’s still the issue of integration. A machine may be able to run 24/7, but if it doesn’t talk to the inventory software or ordering system, then it’s just a fancy wrench. Add cybersecurity concerns on top, and you’ve got factories balancing innovation with risk every day.

Energy and Sustainability: A Ticking Clock

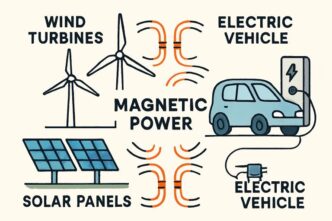

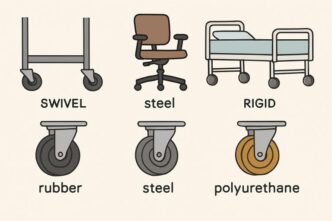

Industries know they need to go greener, but how? Switching to renewable energy, reducing emissions, and eliminating waste isn’t something that happens overnight—or for free. Companies face pressure from governments, customers, and investors to clean up their operations, but the cost of doing so can be high.

Solar panels, wind power, and cleaner fuels are being adopted, but slowly. In some regions, the infrastructure just isn’t ready. Meanwhile, regulations are tightening. It’s a race against time, and the winners will be those who manage to balance sustainability with performance.

Geopolitics: A Wild Card Every Time

Tariffs. Wars. Trade disputes. Political instability. Any one of these can throw an entire operation off course. Even a small diplomatic disagreement can lead to port closures or export bans. For companies with global supply chains, there’s no easy way to prepare for the unpredictable.

Industrial leaders have started to rethink globalization. Some are “reshoring” operations, bringing production back to home countries to reduce exposure. But reshoring brings its own challenges—higher labor costs, limited facilities, and the need to rebuild supply networks from scratch.

Consumer Expectations: Want It Now?

Thanks to two-day shipping and smartphone apps, customers expect everything faster, cheaper, and better. That’s a tough combination for manufacturers. To meet these demands, they need flexible operations that can pivot quickly. But flexibility requires investment—in staff, equipment, software, and planning.

One late shipment, and suddenly your brand’s reputation is on the line. Customer loyalty is fragile, and with so many choices available, it’s easy to lose business to a competitor that simply delivers faster. The pressure to please isn’t just high—it’s constant.

Climate Change: The Invisible Threat

Wildfires in Canada. Floods in Germany. Droughts in California. Climate disasters aren’t abstract problems anymore—they’re directly impacting production, transportation, and worker safety. Heat waves shut down plants. Hurricanes delay deliveries. And rising temperatures wear down machines and buildings faster.

Even planning becomes harder when weather patterns are unreliable. For industries built on predictability, climate change adds a level of unpredictability that’s hard to manage. Insurance costs rise. Backup systems become necessary. And every “worst-case scenario” starts to feel more like the new normal.

Industrial operations are no longer about just producing things efficiently. They’re navigating a complex maze of old infrastructure, new technologies, global politics, and a planet that’s fighting back. Each challenge connects to the next, and solving one problem often creates two more.

Still, there’s resilience in the system. Companies are adapting, investing in smarter tools, rethinking old strategies, and slowly pushing for change. The road is bumpy, but the wheels haven’t stopped turning yet.