Key Takeaways

- Assess load capacity to determine the appropriate caster strength.

- Consider the operating environment, including floor conditions and exposure to elements.

- Choose wheel materials based on the application and surface type.

- Understand the differences between swivel and rigid casters in terms of maneuverability.

- Factor in special requirements such as noise reduction or chemical resistance.

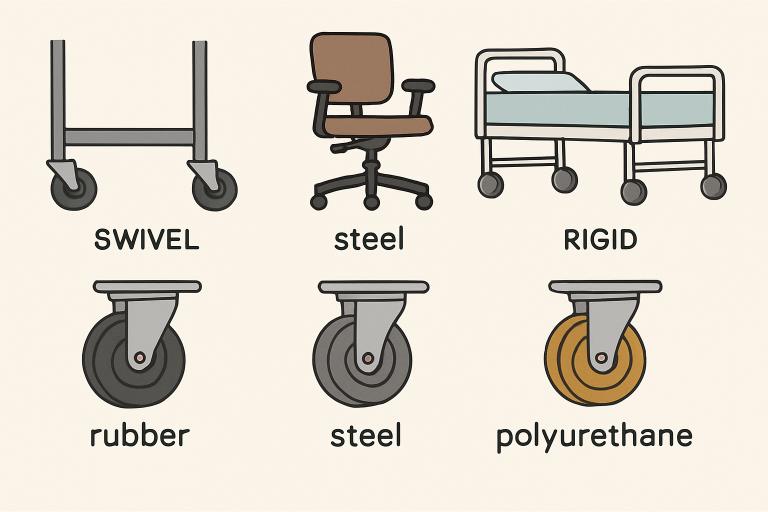

When it comes to efficiently moving equipment, industrial carts, office furniture, or medical devices, choosing the correct casters isn’t just a matter of convenience—it’s a critical decision for productivity and safety. Casters, the wheeled components attached to the bottoms of carts, chairs, and machinery, play a vital role in almost every industry. Selecting the right Albion casters can lead to reduced maintenance, fewer workplace injuries, and longer-lasting equipment. Whether outfitting a new facility or upgrading existing furnishings, understanding the selection process for casters ensures that you strike the right balance between cost, durability, and function.

The sheer variety of caster sizes, wheel materials, and mounting styles can be overwhelming, but selecting the appropriate options will save you time and money in the long run. Factors like load weight, flooring type, and environmental exposure all play key roles. Missing the mark can result in excessive wear, frequent breakdowns, and frustrating maneuverability. That’s why a systematic approach is essential in narrowing down your options and choosing the best caster solution for every application.

Assessing Load Capacity

Before selecting casters for your equipment or facility, identifying the amount of weight they need to support is the most important first step. Proper load capacity ensures the longevity of your investment. Calculate the aggregate load the equipment and its contents will exert, then divide this by the number of casters to be installed. However, don’t forget to add a safety margin—typically 25% higher than the calculated value—to account for uneven loads or occasional overloading. For example, if a trolley weighs 400 lbs and must carry 600 lbs of goods, plan for a total load of 1,000 lbs. Using casters, each should have a load rating of at least 312 lbs to ensure smooth operations and maintain the integrity of your equipment.

Considering the Operating Environment

Caster performance is just as dependent on the environment as on load capacity. The condition of the floors, the potential for exposure to moisture or chemicals, and temperature extremes all play a role in selecting the proper caster type.

- Floor Conditions: On smooth surfaces, such as tile or concrete, softer wheels prevent damage and reduce noise. Polyurethane wheels are a great all-around choice for delicate or finished floors, while hard wheels, such as those made of steel, are better suited to rough concrete or outdoor areas.

- Elemental Exposure: In settings with heavy moisture, outdoor conditions, corrosive chemicals, or high heat, seek casters made from stainless steel or those with special coatings to prevent rust and degradation. Industrial environments often require higher levels of resistance to these stressors, significantly impacting the selection process. For more on matching casters to unique industrial environments, this Popular Mechanics article provides an in-depth analysis.

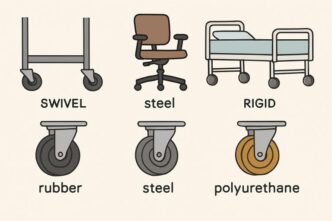

Choosing the Right Wheel Material

The type of wheel material greatly determines the caster’s suitability for different applications. Each material presents trade-offs between weight capacity, surface protection, rollability, and chemical resistance:

- Polyurethane:Highly durable, non-marking, and gentle on indoor flooring.

- Rubber:Delivers quiet movement on hard surfaces, making it ideal for noise-sensitive or hospital environments, but it wears out faster with heavy use.

- Nylon:Lightweight, resistant to water and chemicals, making it excellent for kitchens or wet factories.

- Steel or Cast Iron:Reserved for the heaviest loads and the roughest surfaces, but may harm floors if not paired with mats or treads.

Understanding Caster Types: Swivel vs. Rigid

Two primary caster types exist—each with its specific strengths:

- Swivel Casters:Rotate 360 degrees, enabling sharp turns and navigation in tight spaces. Industries that rely on agility, such as healthcare or food service, favor these for maximum maneuverability.

- Rigid Casters:Roll only in a single direction, providing straight-line stability and enhanced control for long movements or heavy loads, such as warehouse dollies or assembly line carts.

Many businesses opt to pair two rigid and two swivel casters for a balance between stability and easy steering—a common practice across logistics and retail sectors.

Factoring in Special Requirements

Certain applications present unique challenges that basic applications may not address. Casters designed for noise reduction, shock absorption, or chemical resistance may be necessary for optimal results.

- Noise Reduction:Use rubber or soft polyurethane wheels in libraries, hospitals, or office environments.

- Shock Absorption:Pneumatic or semi-pneumatic casters are best for transporting fragile equipment or navigating bumps and thresholds.

- Chemical Resistance:Factories and laboratories should look for casters built from corrosion-resistant materials to ensure uninterrupted operations.

Conclusion

Across factories, warehouses, and office environments, properly selected casters play a critical role in daily operations, quietly supporting the smooth functioning of these spaces. The right casters enhance mobility, streamline workflows, and significantly reduce physical strain on employees, thereby helping to prevent workplace injuries. They also protect floors and equipment, extending the service life of carts, racks, and machinery. By carefully assessing factors such as load capacity, floor conditions, operating environment, wheel material, caster design, and any specialized performance requirements, businesses can make informed and confident decisions. Investing thoughtful effort in caster selection at the outset minimizes maintenance issues, prevents premature failure, and delivers long-term gains in operational reliability, safety, and overall efficiency.