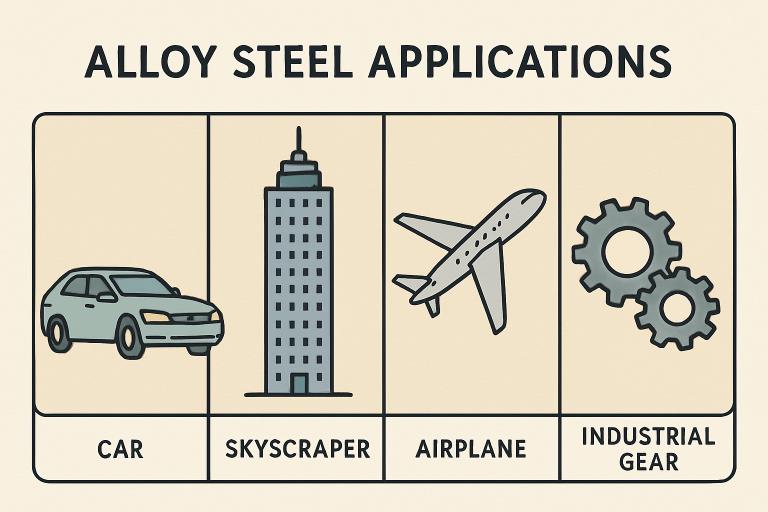

Alloy steel has become a cornerstone of progress in modern engineering, valued for its remarkable blend of strength, flexibility, and durability. These properties stem from carefully selected alloying elements—such as chromium, molybdenum, nickel, and vanadium—which modify the steel’s internal structure, imparting superior mechanical attributes and chemical resistance compared to carbon steel. This unique combination of attributes has propelled alloy steel into a diverse array of engineering sectors, from automotive innovation to the demanding skies of aerospace. Among the many types available, 4150 alloy steel is particularly sought after for projects requiring high performance under extreme conditions, making it indispensable for highly technical and critical applications where materials must not fail.

Today, the adaptability and resilience of alloy steels are ensuring the reliability and longevity of critical applications worldwide. Whether in vehicles that demand lightweight strength or in infrastructures designed to withstand the test of time and natural disasters, alloy steel is often the material of choice for engineers seeking optimal results. The ability to tailor alloy steel through heat treatment and composition adjustments enables a level of customization rarely matched in other classes of metals, further enhancing its appeal in engineering circles.

Automotive Industry

Alloy steel has significantly shaped advancements in the automotive industry by paving the way for lighter, more robust, and safer vehicles. Used extensively in manufacturing engine components, transmission gears, axles, and suspension systems, alloy steel delivers the high strength-to-weight ratio demanded by modern vehicle designs. This property not only enhances the safety and performance of cars but also contributes to greater fuel efficiency, as lighter yet stronger components allow for reduced vehicle weight without compromising structural integrity. The long-term cost savings incurred by improved fuel economy and lower maintenance requirements also benefit manufacturers and consumers alike. Furthermore, automakers rely on the malleability and fatigue resistance of alloy steels to innovate with more complex, safer vehicle frameworks. These properties have empowered engineers to develop lightweight chassis and crumple zones that better absorb impacts, significantly improving crashworthiness for vehicle occupants.

Construction and Infrastructure

In the world of construction and infrastructure, alloy steel plays a pivotal role in achieving ambitious architectural goals and ensuring the safety of public spaces. It serves as the backbone for bridges, skyscrapers, tunnels, and other large-scale projects that rely on both long-term durability and resistance to environmental challenges. The material’s corrosion resistance, coupled with its tensile strength, helps buildings endure harsh weather, seismic activity, and heavy loads. It is especially critical in earthquake-prone regions, as modern alloy steels can be engineered to absorb energy and flex without failing. Modern infrastructure engineers are gravitating toward various alloy steel grades to extend lifespans and minimize ongoing maintenance, ensuring that cities can expand safely and sustainably. Bridges made from alloy steel, for example, are known for requiring fewer repairs, improving safety, and reducing public expenses over time.

Aerospace Engineering

Few industries are as demanding as aerospace engineering, where quality and reliability are both critical and non-negotiable. In an environment where failure can have catastrophic consequences, alloy steels are crucial for aerospace components, such as landing gear, engine shafts, fasteners, and turbine blades, due to their ability to maintain mechanical properties at high temperatures and under extreme stress. The weight-saving characteristics of alloy steel also make it the preferred choice for critical frame elements, directly impacting the performance, speed, and fuel economy of aircraft. The choice of alloy steel in these applications results in safer flight experiences. It contributes to the overall success of ambitious aeronautical engineering missions, from commercial jets to deep-space probes.

Energy Sector

The energy sector—especially oil, gas, and power generation—depends on alloy steel for its unique blend of hardness, toughness, and resilience to high-pressure environments. This material is trusted to operate flawlessly in remote or hazardous settings where access for routine maintenance may be difficult or impossible. Power plants utilize alloy steel in the construction of boilers, turbines, and heat exchangers, whereas oil refineries and pipelines rely on it for transporting corrosive materials and withstanding fluctuating temperatures. These demanding operational environments require materials that can withstand prolonged exposure and extreme conditions without degrading. The integrity of energy infrastructure, including offshore drilling rigs and wind turbine shafts, depends on the strength and reliability of alloy steel products.

Manufacturing and Tooling

High-performance manufacturing relies on alloy steel for the creation of tooling, cutting dies, molds, and components for heavy machinery. Its ability to resist abrasion and retain hardness makes it a staple in high-precision, high-wear environments—delivering the reliability and lifespan needed for cost-effective mass production. Modern high-speed cutting tools and stamping machines, which operate at elevated temperatures and under significant stress, often utilize alloy steels due to their exceptional wear resistance and ability to withstand repeated impact. Manufacturers prize the ability of alloy steel to maintain shape and sharpness, ensuring that each product meets stringent quality standards. This results in reduced downtime and lower maintenance costs, particularly in industries where continuous production is crucial.

Marine Applications

Marine engineering requires a unique set of properties, primarily resistance to corrosion from saltwater and sturdy construction for harsh environments. Alloy steel fulfills these demands in shipbuilding, subsea pipelines, offshore oil rigs, and maritime infrastructure. Specialized alloy grades, containing higher levels of chromium and nickel, are especially effective at withstanding seawater corrosion and impact from floating debris. Sturdier than many other metals in wet conditions, it’s often selected to enhance the safety and performance of vessels and offshore structures that face constant exposure to the elements. Marine engineers rely on these materials to mitigate the risk of catastrophic failure and extend the operational lifespan of expensive assets in the unforgiving ocean environment.

Medical Equipment

Modern medicine has greatly benefited from advancements in alloy steel technology, enabling healthcare professionals to deliver safer and more effective treatments. Surgical tools, orthopedic implants, and certain medical devices are crafted from specialized alloy steels for their biocompatibility, strength, and ability to endure repeated sterilization. The use of stainless alloy steels in devices like bone plates, screws, and joint replacements minimizes the body’s risk of infection and complications. Surgeons and manufacturers alike rely on the reliability of alloy steel to deliver safe outcomes for patients, thereby reducing the risk of breakage or corrosion within the human body. The longevity and resilience of alloy steel help lower hospital costs and ensure that critical medical procedures can be performed successfully time after time.

Final Thoughts

The applications of alloy steel in modern engineering highlight its vital role in driving technological and industrial progress. From enhancing vehicle safety and efficiency to supporting towering infrastructure and pioneering aerospace feats, alloy steel’s flexibility and endurance underpin countless innovations. As demands for sustainability and performance rise across all industries, alloy steel is well-positioned to remain a key material for future engineering breakthroughs, bridging the gap between what is possible today and tomorrow’s technological dreams.