Maintaining a grinder allows it to operate using various materials, including steel and wood, and run smoothly. If you are looking to buy more machinery, some dealers sell new and used equipment. Here are more details about when to maintain Blanchard grinders:

Each Day

A technician cleans components like the guards, table, and magnetic chuck; this helps eliminate buildup that scratches the machine. When the coolant is low, the grinder strains to operate, which might result in overheating. To prevent this risk, it’s beneficial to check the coolant and add more if the level is low.

Since friction can damage the equipment before you use it to its fullest potential, a specialist will check and refill the lubrication reservoirs. An expert inspects the spindle; if it’s producing peculiar noises, they address any issues. Before using the grinder, technicians balance the wheels so that they create surfaces evenly.

To stop water from corroding some parts in the machine, a professional drains moisture from the air lines and filters. During daily maintenance, you can check if oil is flowing properly to prevent wear on the machine. Before use, it’s beneficial to dress the grinding wheel, so it shapes materials accurately.

Every Week

Inspect and tighten all mounting bolts to prevent Blanchard grinders from vibrating too much. A qualified technician should clear the coolant tank to get rid of sludge that blocks the machine and interferes with cooling. Dust may accumulate in the electrical cabinet, and wiping off debris prevents short circuits.

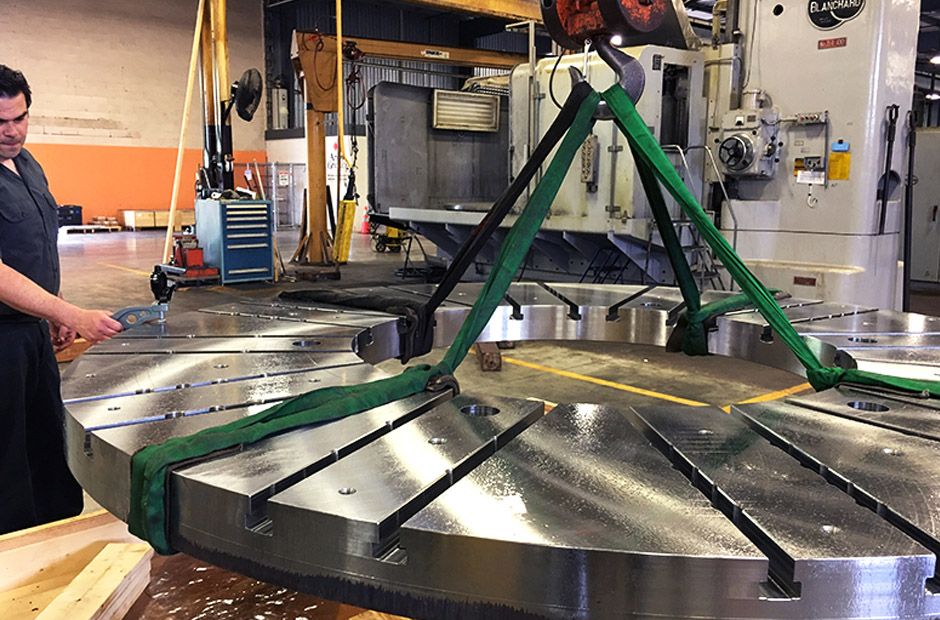

In the hydraulic system, a specialist checks whether the pump is delivering the right pressure. This expert also inspects valves to see if they are opening and closing well to control fluid flow. If the rotary table drive isn’t running smoothly, the operator adjusts it to make sure the machine moves steadily; this helps make sure that various materials, such as cast iron, steel, copper, and some plastics, come out with flat and smooth surfaces.

Each Month

A specialist may oil the feed screw; this helps the grinding head move vertically and cut at the right depth. A technician should also check the limit switches and safety interlocks to see if they are working well and to keep the machine safe. Your monthly tune-up may include adjusting gib strips on some machines, so they move smoothly.

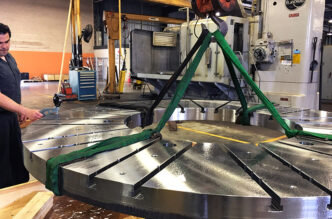

If the spindle bearings are beyond repair, replace them to help the machine perform properly. A professional can grease these components; this helps to prevent friction, which damages the machine. Testing the chuck controller allows components to magnetize and hold parts securely when the grinder is running.

Every Three Months

You can change the oil filter every few months to help eliminate any type of contaminants in the hydraulic system. One way to prevent the system from leaking is by checking all fittings and hoses for cracks. A technician disinfects the coolant tank to prevent mold from growing and corroding the equipment. It’s beneficial to clean and replace lube filters so that dirt does not reach moving parts; you can also clean the oilers so that oil moves freely and lubricates other components in the machine.

After a Year

After using the grinder for a year, check all parts of the Blanchard grinder to make sure they are in good condition and do not have damage that needs to be fixed. Regrind the magnetic chuck to help it function correctly if you have used the grinder for many tasks. Since some pumps wear out over time, it might be time to replace them. Technicians inspect the table’s rotation to see if it turns accurately. Examine the spindle, and listen to any noises so that you can buy new bearings if needed. Replacing hydraulic and lubrication fluids allows you to get rid of pollutants in the system and prolong the lifespan of your Blanchard grinder.

Buy Quality Blanchard Grinders Today

You can buy a new or used grinder from a reliable handler; this allows you to handle more work and create items that have even surfaces. Choose a big machine or a smaller one, depending on what you need to grind. Visit a trusted website today to see what it has to offer and view available grinders.