The Tiny Engines Behind Tomorrow’s Devices

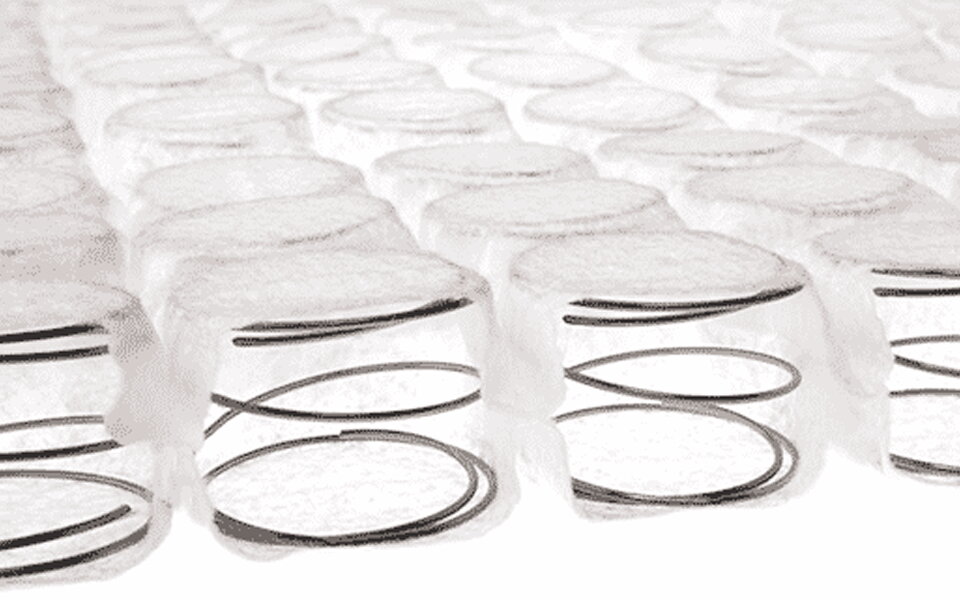

Imagine a thread of metal as tiny as a hair, woven into a perfect spiral to power gadgets that listen, pulse, scan, and heal. Micro coils—compact, carefully built inductors—convert magnetic fields into movement, power, and signal clarity. Micro coils quietly make treatment smaller, safer, and smarter in contemporary medicine’s most trusted equipment.

Size isn’t their specialty—control is. To optimise inductance, sensitivity, and efficiency, engineers adjust coil geometry, wire gauge, turns count, and core materials. Biocompatible alloys, whisper-thin insulation, and housings that withstand years of motion, moisture, and body chemistry are chosen. The benefit: devices that match the body’s cycles and reduce patient burden.

Pacemakers and ICDs: Rhythm, Reliability, and Miniaturization

Pacemakers and ICDs use coils to accurately measure electrical activity and communicate and power across the skin without cumbersome connectors. Implant micro coils constitute the heart of the telemetry loop, allowing doctors to noninvasively assess and alter settings. Some systems offer inductive power transmission for recharging, reducing battery needs and increasing life.

The coil work doesn’t stop at the can. Leads that deliver pacing or shocks balance flexibility with durability, often incorporating fine wire coils designed to withstand millions of cardiac cycles. Materials like platinum–iridium and MP35N, paired with polymer insulations such as polyimide or parylene, help the system stay stable in the salty complexity of the human body. The result is elegant: precise pulses, dependable sensing, and smaller devices patients barely notice.

MRI Systems: Sharper Images with Micro-Scale Precision

If the MRI suite is a symphony of magnets, micro coils are the virtuoso soloists. While the main and gradient coils create broad magnetic landscapes, arrays of small radiofrequency (RF) receiver coils sit close to the anatomy and soak up faint signals with exquisite sensitivity. The closer a coil is to the tissue, the stronger the signal-to-noise ratio—meaning clearer images at finer detail.

Engineers manufacture these coils in small loops, phased arrays, or flexible, conformal designs that hug the head, spine, or joints. Coil design, Q-factor, and decoupling procedures limit cross-talk and artefacts, giving radiologists clean edges and nuanced textures for fast, reliable diagnosis. Micro coil construction gives physicians cinematic clarity from undetectable physics.

Hearing Aids and Cochlear Implants: Turning Signals into Sound

The magic of restored hearing involves tiny coils. Micro coils in balanced armature receivers drive small diaphragms to form natural-sounding sounds in a shell that disappears behind the ear. A “telecoil” lets users tap directly into loop-enabled venues for pure, noise-free sound.

Different coil trick: transcutaneous inductive link for cochlear implants. The external sound processor and implanted receiver’s micro coils magnetically transfer power and data across the skin, avoiding percutaneous hookups and infection risk. Well-designed coils and circuitry in the implant convert sound into auditory nerve pulses. Small coils have a big influence since the device must remain comfortable 24/7.

Neurostimulators: Precision Pulses for Brains and Nerves

Today, implantable neurostimulators give tailored electrical therapy to treat chronic pain, epilepsy, and Parkinson’s disease. Micro coils offer stealth by supporting wireless telemetry, power transfer, and field coupling into adjacent tissue. As therapy becomes more personalised, coils with tightly controlled inductance and minimal loss allow finer modifications without exhausting batteries.

Mechanical demands are high. Leads bend with every movement; coatings must withstand moisture and protein deposition; performance must not wander. Winding uniformity, fatigue-resistant metals, and hermetic sealing aren’t simply nice-to-haves—they’re the difference between a device that lasts a decade and one that fails shortly.

Tools of the Procedure: Catheters, Endoscopes, and Energy Delivery

In the operating room and cath lab, micro coils turn intricate procedures into precise choreography. Catheter tips can embed micro coils for electromagnetic tracking, letting navigation systems triangulate position in real time—think GPS for the vasculature. Some ablation catheters use coil-based sensors to monitor temperature or motion, helping physicians dose energy without collateral damage.

Reduced-invasive endoscopes and tools benefit. Compact motors and actuators use tiny coils for smooth, controllable movement in tight places, while micro-scale transformers and inductors regulate power on flexible circuits that snake through the body. Again, lighter equipment, smaller incisions, faster recuperation, and confidence.

Inside the Craft: Materials, Winding, and Reliability

For every reliable gadget, coil engineering borders on obsession. Copper wire is efficient, platinum–iridium wire is implant-safe, and MP35N wire is strong and corrosion-resistant. Either enamel, polyimide, or parylene insulation is chosen for dielectric strength, thinness, and sterilisation tolerance.

Precision mandrel winding and flexible substrate planar microfabrication are winding processes. Engineers balance trade-offs: more turns increase inductance but add resistance and heat; ferrite or powdered cores promote coupling but inflate size; and litz designs reduce AC losses for higher-frequency links. Medicine has no patience for fragile parts, thus designs must pass drop, bend, soak, and sterilisation tests.

Interference follows. Devices like hospital equipment and MRI scanners use shielding, filtering, and careful planning to deal with electromagnetic chaos since coils are sensitive. A smart coil keeps signals clean and patients safe.

FAQ

What is a micro coil?

A micro coil is a tiny, precisely wound inductor that converts electrical energy to magnetic fields (and back) for sensing, power transfer, and signal work. In medicine, they enable miniaturization and high performance inside compact devices.

How small are micro coils?

They can be millimeters down to sub-millimeter in diameter, with wire as thin as a human hair or finer. Size depends on the application’s power, frequency, and sensitivity needs.

Which materials are commonly used?

Copper is common for efficiency, while implantable coils often use platinum–iridium or MP35N for biocompatibility and corrosion resistance. Insulations include enamel, polyimide, and parylene.

Do micro coils make MRI images better?

Yes—small RF receiver coils placed close to anatomy capture stronger signals, improving image clarity and detail. Arrays of these coils help cover larger regions without losing resolution.

Are micro coils safe inside implantable devices?

When designed with biocompatible materials and proper sealing, they’re safe and stable for long-term use. Rigorous testing verifies durability, electrical performance, and tissue compatibility.

Can coils enable wireless charging for implants?

Many implant systems use inductive links—paired coils across the skin—to transfer power and data without connectors. This reduces infection risk and can extend battery life.

Do micro coils heat up during use?

Any coil can produce heat under load, but medical designs manage current, frequency, and duty cycle to keep temperatures within safe limits. Materials and thermal paths are selected to dissipate heat efficiently.

How are implantable coils sterilized?

They’re built to withstand validated sterilization methods like ethylene oxide or gamma, depending on materials and packaging. Design choices ensure performance remains stable after sterilization cycles.

What’s the difference between RF and gradient coils in MRI?

RF coils transmit and receive radiofrequency signals, while gradient coils rapidly shape the magnetic field to localize signals. Micro coils typically refer to small RF receivers close to the body.

How long do implantable coils last?

With proper materials and sealing, implantable coils are designed to last for the life of the device, often many years. Longevity is verified through accelerated aging and fatigue testing.